As we step into a world increasingly aware of its carbon footprint, the quest for sustainable energy solutions is more crucial than ever. Amidst the myriad of green technologies, one that stands out is the alkaline electrolyzer plant. This isn’t just another piece of engineering; it’s a beacon of hope in our battle against climate change.

What’s an Alkaline Electrolyzer Plant?

To understand an alkaline electrolyzer, think of it as a futuristic machine that takes water (yes, plain old H2O) and zaps it with electricity to split it into hydrogen and oxygen. The cool part? The hydrogen produced is a clean fuel — it can power cars or be converted into electricity without any nasty emissions, just water vapor!

But there’s a catch. Electrolyzers need to be efficient, reliable, and affordable to be part of our everyday energy solution. This is where dynamic modeling comes into play.

Dynamic Modeling or The Brains Behind the Operation

Dynamic modeling is like the brain of an electrolyzer plant. It’s a bunch of mathematical equations that predict how the system behaves under different conditions. Think of it as a super-detailed simulator. By tweaking variables in the model — like temperature or pressure — scientists can figure out the best way to run the plant.

The key here is the term “dynamic.” It means the model considers how things change over time. Like a video game that simulates a race car’s behavior on different tracks, dynamic modeling helps engineers test the electrolyzer in a virtual world before any real-world trial.

The Power of Differential Algebraic Equations (DAE)

The backbone of dynamic modeling in electrolyzers is something called Differential Algebraic Equations or DAEs. These aren’t your average high school math problems. DAEs can describe how energy and mass flow through the system, taking into account the laws of thermodynamics and fluid dynamics.

By solving these equations, the model can tell engineers how the electrolyzer will react to changes, like a sudden increase in power supply or a fluctuation in water quality. This insight is crucial for designing a plant that’s both safe and efficient.

Thermodynamic Libraries & The Encyclopedia of Energy

Imagine having a library that contains all the knowledge about how substances behave under different temperatures and pressures. That’s what a thermodynamic library does for dynamic modeling. It’s a collection of data and equations that describe the thermophysical properties of the materials involved in the process.

With this library, the model can accurately predict things like how much hydrogen will be produced at a certain temperature or how efficient the electrolyzer will be under specific conditions. It’s like having a cheat sheet for understanding the complex interactions in the plant.

Mapping the Plant’s Heartbeat

To make sense of all this data, engineers use steady-state diagrams. These are graphical representations of the plant’s operation at a fixed point in time. They show the relationship between different variables, like how the amount of hydrogen produced varies with temperature.

These diagrams are essential for troubleshooting and optimizing the plant. If something’s not working right, a look at the steady-state diagram can often point engineers in the right direction.

Clean Energy for All

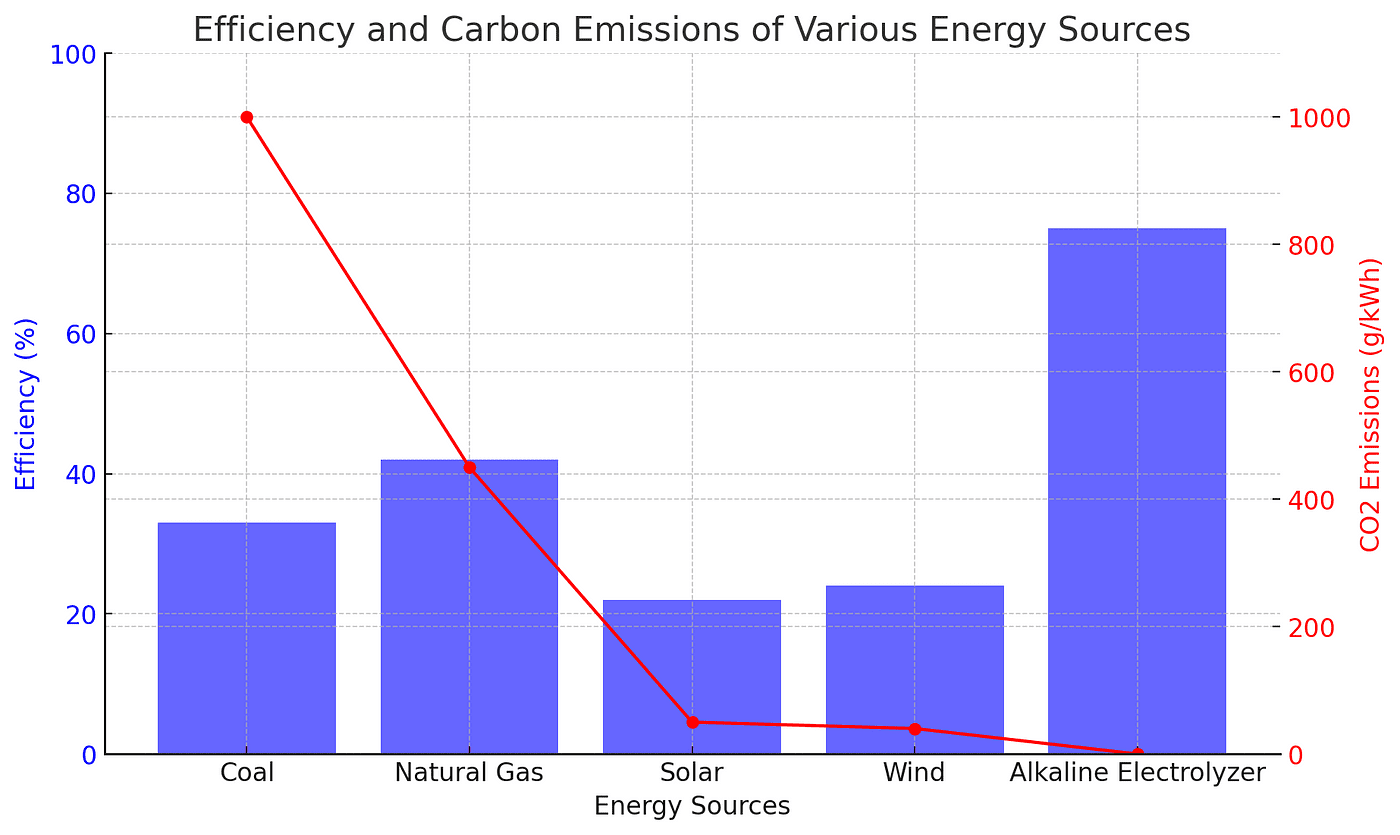

The ultimate goal of all this high-tech modeling is to make alkaline electrolyzer plants a viable option for large-scale hydrogen production. We’re talking about a future where these plants could be hooked up to renewable energy sources like wind or solar, producing hydrogen fuel with virtually zero carbon emissions. Let’s take a closer look at how alkaline electrolyzers stack up against other energy sources in terms of efficiency and environmental impact with this revealing graph:

This isn’t just a pipe dream. Research and development in this field are moving fast, and dynamic modeling is a big part of that progress. By understanding and optimizing these plants, we’re one step closer to a sustainable energy future.

The Journey Ahead

The journey to a cleaner, greener world is filled with challenges, but also with incredible opportunities. Alkaline electrolyzer plants, powered by dynamic modeling, stand at the forefront of this journey. They’re more than just pieces of machinery; they’re symbols of our commitment to a sustainable future.

As we continue to refine and improve these technologies, we move closer to an era where clean energy is not just a luxury, but a given. It’s an exciting time to be alive, especially for those of us passionate about making a difference in the world. The future is bright, and it’s powered by clean energy.

About Disruptive Concepts

Welcome to @Disruptive Concepts — your crystal ball into the future of technology. 🚀 Subscribe for new insight videos every Saturday!